Fly Ash from Coal Combustion as a New Source of Rare Earth Metals

Rare earth metals (REMs) is a group of elements, which has a strategic usage in the production of high-end technology such as space satellites or defence technologies. Currently China controls the majority of sources producing REMs.

As the production of high-end technology is expected to rise, the significance of REMs will increase as well. This pressure will lead to find other sources of REMs. The traditional approach of recycling won’t be enough, since the demand for REMs will be growing. This article highlights newly discovered alternatives leading to new sources of REMs, which are more freely accessible to developed countries (namely fly coal ash from coal-firing power plants). This article focuses on germanium metal, which is most likely to be most economically viable for large scale separation of fly ash.

Current development in the area of production of REM

Currently China exports 90 % of the conventional sources of REMs. This situation is not optimal due to the strategic importance of REMs in production of high-end products such as consumer electronics, military defence equipment or satellites. Shortages of REM can cause strategic failures in Europe, East Asia and North America, since these countries will face increased consumption of REM in the next 30 years.

Traditionally REMs are obtained either by mining or by recycling. However, there is another perspective source, which is fly ash from coal combustion power plants. Depending on the given coal type and the facility conditions fly ash coming from these facilities contains traces of REM.

Rare earth metals description

REM is one of a group of 17 chemical elements. Despite their name, rare earth elements are relatively abundant in the Earth's crust, with Cerium being the 25th most common element on Earth at 68 parts per million, or as abundant as copper. They are not especially rare, but they often appear together in nature.

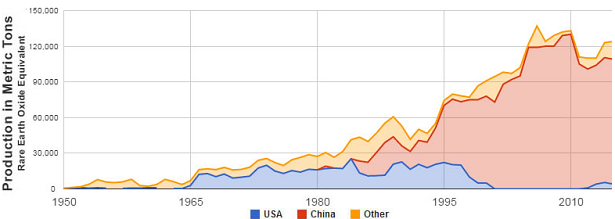

Until 1948, most of the world's REM production was sourced from placer sand deposits in countries of India and Brazil. In the 1950s, South Africa became the world's biggest rare earth source, after large veins of REM bearing monazite were discovered. Through the 1960s until the 1980s, the Mountain Pass REM mine in California was the main producer. Today, Indian and South African deposits continue to produce some REMs concentrates, but they are dwarfed by the quantities of Chinese production. In 2010, China produced more than 95% of the world's REM supply. Most of it came from the region of Inner Mongolia. All of the world's heavy REMs (such as dysprosium) come from Chinese REM sources such as the polymetallic Bayan Obo deposit. The development can be seen in picture 1 bellow. New demand has recently strained limited free supply, and there is growing concern that the world may soon face a lack of available REMs.

Picture 1: Rare Earth Metals Production

Source: Geology.om 2016

REMs have a high range of usage in various high-tech industries. Gallium, Germanium is used in satellites. Europium has application in TV screens. Scandium is sued in flight guidance of military rockets.

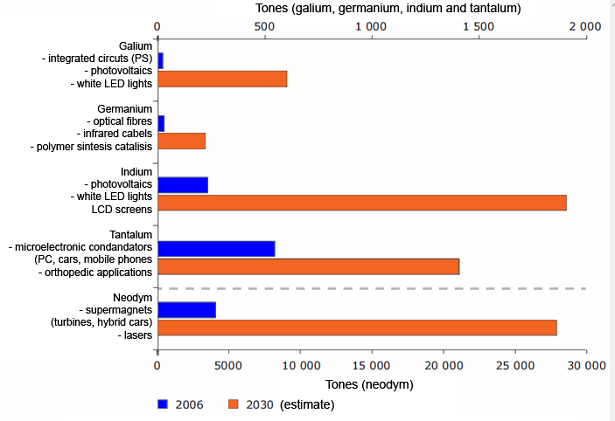

The potential of REMs with their future application up to the year 2030 can be seen in the figure 2.

Figure 2: Rare Earth Metals Production

Source: EEA 2016

The highest increase of consumption is expected to be seen at neodymium and indium elements. Still the consumption of all other metals is expected to increase dramatically, so finding new sources of REMs is a key strategic necessity for developed countries, where many industrial sectors depend on the uninterrupted supply of REMs.

The Agenda of European Union

The supply crunch caused by decreased export from China in 2010-2011 was an alarm bell for businesses and governments. This signals a future in which REMs should not be taken for granted. Tightening export restrictions by near-monopolist China put rare earths in the headlines and set off a speculative rally that drove up prices by between four and nine times in less than a year. Some European manufacturers were forced to fly supplies from one plant to another to avoid production outages.

The 2014 Communication of the European Commission on the review of the list of critical raw materials for the EU and the implementation of the Raw Materials Initiative presents an updated list of critical raw materials and provides a summary of the upcoming activities related to the Raw Materials Initiative, the European Innovation Partnership on Raw Materials and the part of research programme Horizon 2020 that concerns raw materials.

This agenda should contribute to make European industry more competitive. It should as well assist incentivise to promote European production of critical raw materials and facilitate the launching of new mining activities.

Secondary Energy Products

Separation of REMs from coal ash is a highly researched topic from 2005 onwards. There were patents on this technology submitted by research teams from China, USA and Finland (of EU).

Another source of CCPs containing REMs are CCPs stored in landfill near power plants. These landfills are territories namely used for land re-cultivation after mining process. These places contain millions of tons of CCPs. The overall content of REMs in these landfills is substantial, however the samples of these landfills tend to be very variable due to the presence of clay layers and mixtures of different types of CCPs.

Developing technologies

Separation of REMs from coal ash is a highly researched topic from 2005 onwards. There were patents on this technology submitted by research teams from China, USA and Finland (of EU).

Chimenos and Valle-Zermeñoa in their article titled “Arsenic and antimony removal by oxidative aqueous leaching of IGCC fly ash during germanium extraction” also focused on recovery of germanium from the fly ash. Their approach however caused significant amount of acid waste. Zhang and Xu focused on making the extraction process more environmentally friendly and increased the extraction ratio of germanium up to 94,6 %. Arroyo and Fernandez-Pereira had the same level of success as previous researchers. Their hydrometallurgical recovery method discovered in Spain of germanium from coal gasification fly ash yielded extraction yields higher than 90 %. Their research team was able to conduct one year later a pilot study in field conditions at a Spanish power plant, where they were able to extract 50 % of germanium in the fly ash.

About the author:

S. Buryan is a researcher focusing on environmental and development issues of economics of the EU. He took part in variety of university research projects. Email: simon.buryan@vse.cz

Acknowledgement:

The results of this article were obtained thanks to research grant of University of economics: VŠE Praha F2/36/2016 (IG271036) “Metodologie ekonomického, politického a právního hodnocení zavádění environmentálních inovací do praxe”.

Further reading on the topic in our library:

- Putten Frans-Paul van der (ed.) - Europeand China's new silk roads - https://goo.gl/ZBubsm

- Němečková, Tereza (ed.) - Vzestupasijských zemí v mezinárodním obchodu - https://goo.gl/88o3nv

- Smil, Vaclav - China's energy - https://goo.gl/AVfJSx